For the very best CNC Swiss screw machine services in the industry, including medical CNC screw-machining services, our team at Tri-Gon is here to help. With three generations of experience, we have honed our processes and techniques to become leaders in precision CNC Swiss screw machining.

Whether you’re looking for miniature parts, medical CNC screw-machining services or other precision cnc screw machining related needs, we have the expertise and equipment to exceed your expectations. Our commitment to quality, consistency and accuracy is reflected in every project we take on. Contact us today to learn more!

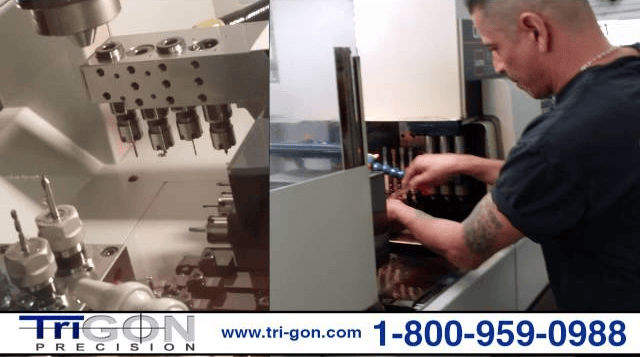

Our Precision CNC Swiss Screw Machines

Committed to our clients’ success, Tri-Gon works closely with each client to provide solutions to any challenging shaft, pin or bushing applications. We offer precision CNC Swiss screw machining services that utilize the latest technology to manufacture the custom parts your application requires. Tri-Gon prides itself on its capability to deliver large quantities quickly, and with extreme accuracy. Our skills, expertise and state-of-the-art equipment allows us to manufacture ultra-high precision components. We work efficiently and keep our stock high to give our customers quick turn-around times.

Our CNC Swiss screw machines, also called CNC turning machines or lathes, are ideal for manufacturing small and long, slender parts, or any other part that requires close precision. CNC Swiss screw machines feature more sets of tooling than automatic machines, making them capable of performing several operations on the same piece in a shorter amount of time and with more precision. Essentially, these machines turn metal down to a desired size by spinning very quickly on a rotating lathe. Swiss screw machines are fast and extremely accurate, holding up to .0001 tolerances.

We realize the importance of maintaining our machinery to offer the best quality products, and this is why our CNC machines are regularly calibrated or upgraded to achieve maximum manufacturing potential. Whether you are in the robotics, defense, communications, medical, mining or aerospace industry, you can trust us to perform your CNC screw machining services quickly and accurately.

Specializing in Medical and Aerospace CNC Swiss Screw Machine Services

At Tri-Gon, we specialize in medical and aerospace CNC Swiss screw machine services, providing high-precision components for these demanding industries. With a focus on quality and consistency, we have experience working with a variety of materials such as titanium, Inconel, stainless steel, Aluminum, plastic and many more. Our team is well-versed in the specific requirements and regulations of these industries, ensuring that all parts are manufactured to their strict standards.

For medical CNC screw-machining needs, we understand the critical importance of precision and accuracy. Our state-of-the-art equipment and experienced technicians allow us to produce medical components with tight tolerances, helping to improve patient outcomes and ensure safety.

In the aerospace industry, every component must meet strict print specifications. With our CNC Swiss screw machines, we are able to manufacture highly precise parts that meet these requirements and exceed expectations. We also have experience working with exotic materials commonly used in aerospace applications.

CNC Swiss Screw Machining and Close Tolerance Grinding

In addition to CNC Swiss screw machining of components, Tri-Gon offers grinding capabilities for closer tolerances. Such as:

- Precision O.D., Grinding between centers

- I.D. Grinding

- Centerless Grinding

- Surface Grinding

- Cylindrical Grinding

- Concentricity to .000025” or less

- Precision grinding capabilities that can hold tolerances to .000025”

- Turning holding tolerances to .0001”, producing high precision small parts up to 13/16” diameter, length to 6’, volume of 1 to 150,000

- Working with stainless steel, aluminum, plastics, titanium, silver and other exotics.

- Screw machine parts are small parts turned on a lathe, allowing for mass produced parts with repeatability and accuracy

- Swiss Screw machine parts are turned on a Swiss style lathe, EXTREMELY accurate to tenths of a thousandth of an inch.

- Specializing in precision shaft work utilizing both CNC Swiss Screw Machining and Grinding capabilities.

To offer more capabilities from one point of contact, Tri-Gon is an active participant in the Integrated Supply Chain’s Management Team.

At Tri-Gon, our commitment to timely delivery, consistent quality and minimized cost exceeds all industry standards.

Contact the highly qualified staff at Tri-Gon Precision today to discuss your CNC Swiss screw machining and turned parts application.