Recent Blog Posts

Precision Machine Shop

Colorado Springs, CO

Over 50 Years of Experience

All Inclusive Machining Services

On-Time Delivery

Tri-Gon Precision has delivered high-precision CNC machining, milling, Swiss screw machining, and grinding services since 1973. Based in Colorado Springs, CO, we are a well-known, trusted name in the industry.

Proudly Serving Businesses Across the United States

Hours:

Request Lorem Epsom

Hero Request Form

Thank you for contacting us.

We will get back to you as soon as possible.

Please try again later.

Precision Machining for Complex Parts

Tri-Gon Precision, Inc stands at the forefront of the machining industry in Colorado Springs, CO. With over three decades of experience, we've honed our skills to deliver unparalleled precision in every project we undertake. Our family-owned, minority, and woman-operated business takes pride in our ability to handle complex parts with close tolerances, ensuring that each component meets the highest standards of quality and accuracy.

Innovation is at the core of our operations. From prototyping to full-scale production, we employ cutting-edge technology and techniques to bring your designs to life. Our team of skilled machinists and engineers work tirelessly to guarantee customer satisfaction, fostering close relationships with our clients throughout the entire manufacturing process. Whether you're in aerospace, medical, or any other industry requiring precision-machined parts, we're committed to exceeding your expectations. Ready to experience the Tri-Gon difference?

Contact us today and let's discuss how we can turn your complex machining needs into reality.

Why Choose Us

All Inclusive Services

Over 50 Years of Experience

Customer Satisfaction Guaranteed

Proudly Family & Woman-Owned

Close Customer Relationships

On-Time Delivery

Finishing Services

Machining Services

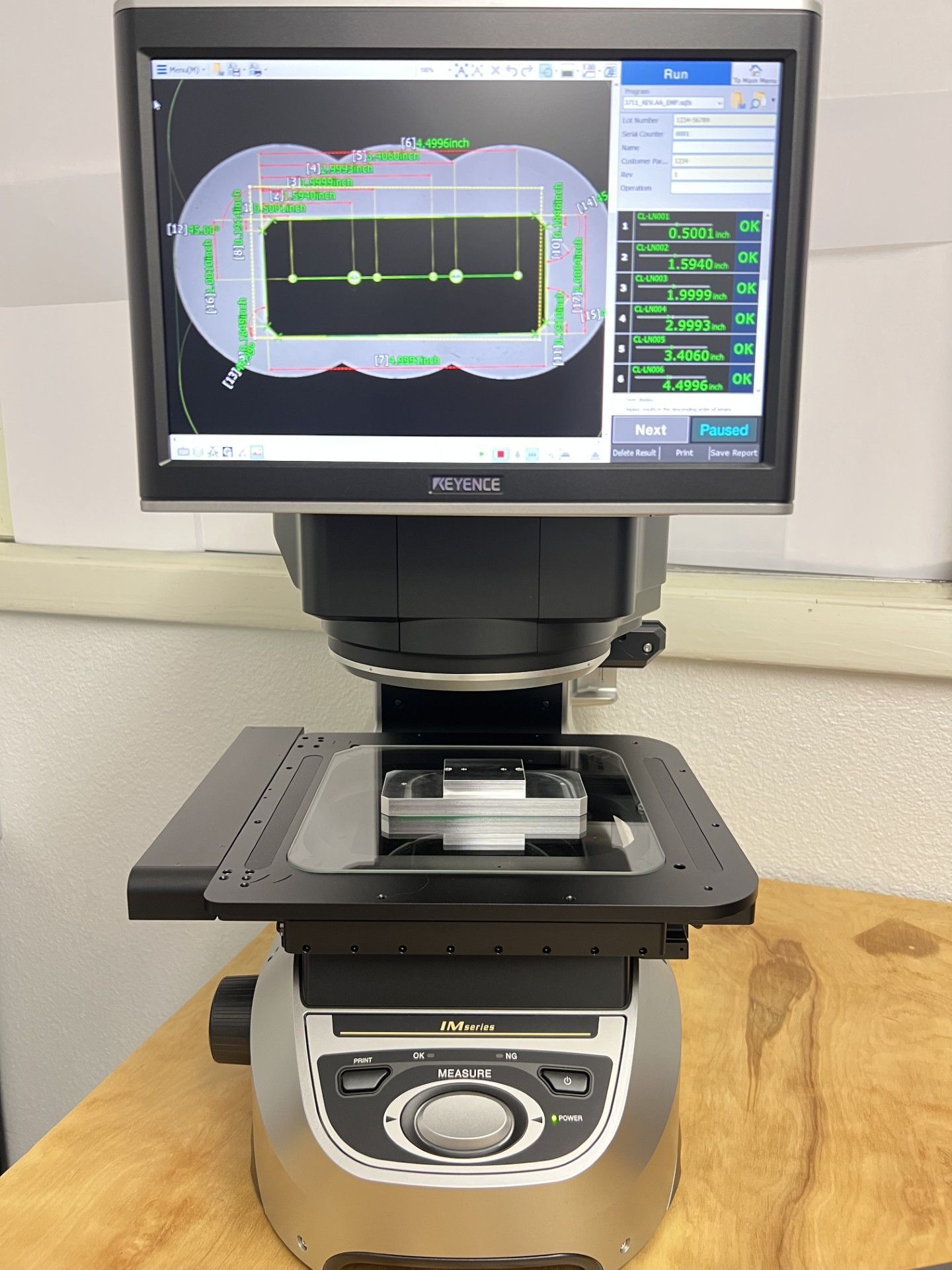

We offer a comprehensive range of machining services tailored to meet your specific requirements. Our state-of-the-art CNC machines and expert operators ensure precise, repeatable results for even the most intricate parts. From milling and turning to grinding and EDM, we have the capabilities to handle diverse materials and geometries with exceptional accuracy.

Value Added Services

We go beyond traditional machining to offer value-added services that streamline your manufacturing process. From design assistance and prototyping to assembly and quality control, we provide end-to-end solutions. Our commitment to innovation means we're constantly exploring new ways to optimize production, reduce costs, and improve the overall quality of your parts.

Here's what our satisfied customers are saying...

At Tri-Gon Precision, Inc, we take pride in providing exceptional precision machining services to our customers. We would be grateful if you could share your thoughts about our <<business>> with others. Your feedback helps us improve and helps others make informed decisions. Please take a moment to leave a review of Tri-Gon Precision, Inc and let others know what you think.

Frequently Asked Questions

How long has Tri-Gon Precision been in business?

We’ve been providing precision machining solutions for decades, building a strong foundation rooted in experience and consistency. As a reliable precision machine shop in Colorado Springs, CO, we’ve continually adapted to new technologies and evolving manufacturing demands. This long-standing presence reflects our commitment to quality, reliability, and long-term partnerships.

Our experience allows us to approach projects with a deeper understanding of both challenges and expectations. We have seen how requirements change over time and know how to stay agile without sacrificing precision. That perspective helps us support customers who value stability and proven performance.

Where are you located, and who do you serve?

As a leading precision machine shop in Colorado Springs, CO, our machining and production operations support customers across the U.S. who rely on high-precision components. Our facility is designed to maintain close oversight of quality and workflow.

While we operate from a single location, our reach extends far beyond it. We work with customers in multiple regions and industries, maintaining consistent communication regardless of distance. This approach allows us to deliver dependable results without compromising responsiveness.

How do you communicate throughout a project?

We prioritize clear and consistent communication throughout every stage of a project. From initial discussions to final delivery, our team remains engaged and accessible. This ensures alignment on expectations and timelines.

Ongoing communication helps prevent surprises and supports smoother execution. We believe strong collaboration leads to better outcomes for everyone involved. That mindset is central to how we build lasting partnerships.

What materials do you commonly machine?

We machine a wide variety of materials to meet different performance, durability, and application needs. Our reputation as an experienced precision machine shop in Colorado Springs, CO is built on our ability to handle metals, plastics, and specialized alloys selected based on each project’s requirements. Material selection plays a critical role in achieving precision and long-term reliability.

Our team carefully evaluates how each material behaves during machining. We consider factors such as tolerance stability, surface finish, and end-use conditions. This attention to detail helps ensure the finished component performs exactly as intended.

Do you specialize in small or highly detailed components?

We have extensive experience producing small, intricate components that require close tolerances. These parts often demand specialized equipment and a disciplined machining approach. Precision at this scale requires careful attention to every detail.

Our team is well-versed in managing the challenges that come with miniature and complex parts. We focus on consistency, repeatability, and accuracy throughout production. This capability allows us to support applications where even minor deviations matter.

Can you support both small and large production runs?

We support projects ranging from early-stage prototypes to ongoing production runs. Our processes are designed to scale efficiently while maintaining consistency and repeatability. This flexibility allows us to adapt as customer needs evolve.

Whether a project requires a limited quantity or sustained production, our precision machine shop in Colorado Springs, CO applies the same level of precision and oversight. We focus on process control to ensure quality remains consistent throughout the lifecycle of a part. This approach helps customers plan for growth with confidence.

Do you offer engineering or design support?

We collaborate closely with customer engineering teams to support manufacturability and efficiency. Early involvement allows us to review designs and identify opportunities for improvement. This collaboration often helps reduce production challenges later in the process.

Our input focuses on practical considerations that support reliable machining outcomes. We aim to help streamline designs while preserving their intended function. If you’re looking for a precision machine shop in Colorado Springs, CO that goes above and beyond standard machining services, count on our team to deliver exceptional results.

What documentation and traceability do you provide?

We understand that documentation is essential for many applications, particularly those with strict quality requirements. Our processes support detailed records and traceability aligned with customer expectations. This helps ensure accountability at every stage of production.

Providing clear documentation allows customers to verify compliance and maintain internal records with confidence. We take pride in delivering not just parts, but also the supporting information that confirms their quality; we believe that this transparency strengthens long-term relationships.

Can you help manage inventory or ongoing production needs?

We offer flexible production and delivery programs designed to support consistent supply. These options help customers reduce downtime and maintain steady operations. Planning ahead is key to long-term manufacturing success.

By aligning production schedules with usage patterns, we help simplify inventory management. At our precision machine shop in Colorado Springs, CO, our goal is to support efficiency without creating unnecessary overhead. This proactive approach benefits both short-term needs and long-term planning.

What secondary or finishing services are available?

We coordinate a range of finishing services to support both functional and aesthetic requirements. These processes help ensure parts are ready for use upon delivery. Managing these steps as part of the overall workflow improves consistency.

By overseeing finishing alongside machining, we reduce the need for multiple vendors. This streamlined approach helps maintain quality control from start to finish. Customers benefit from a simpler, more efficient process.